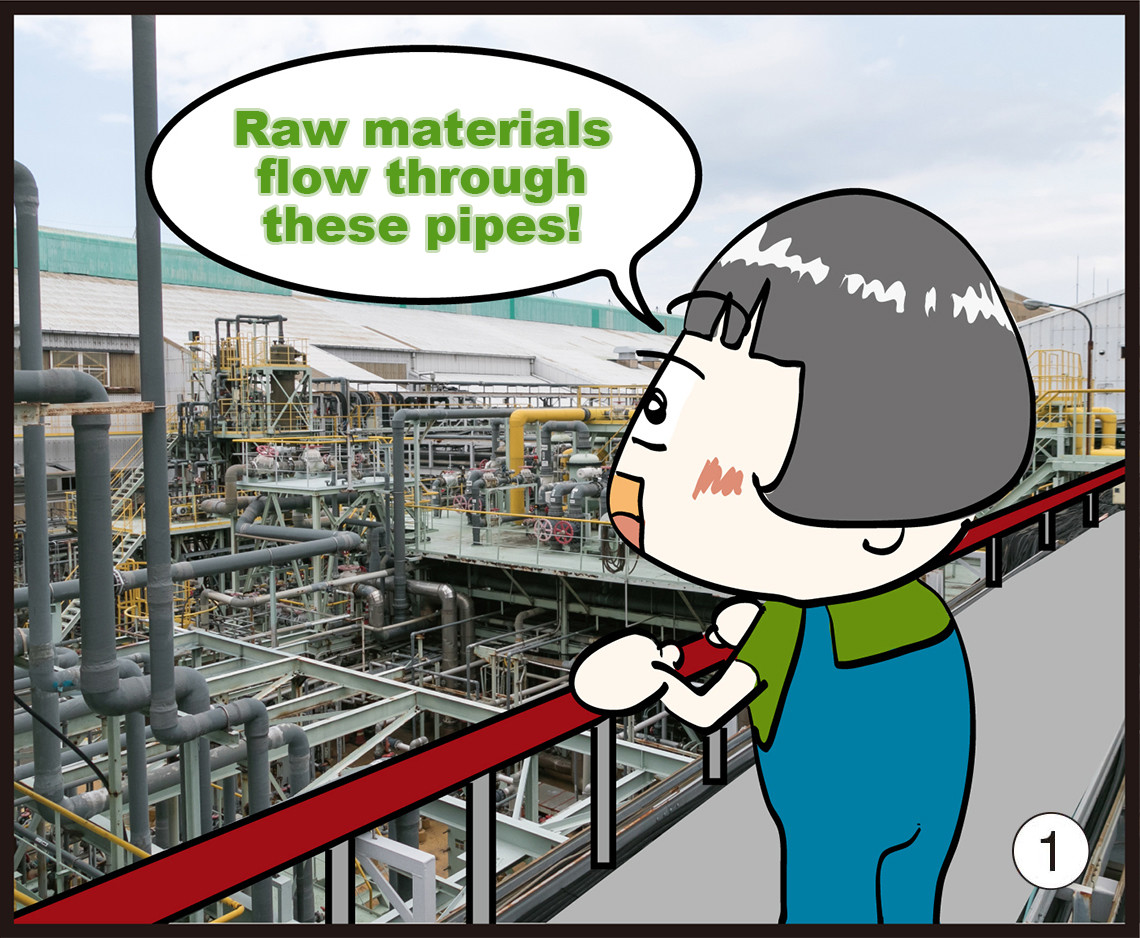

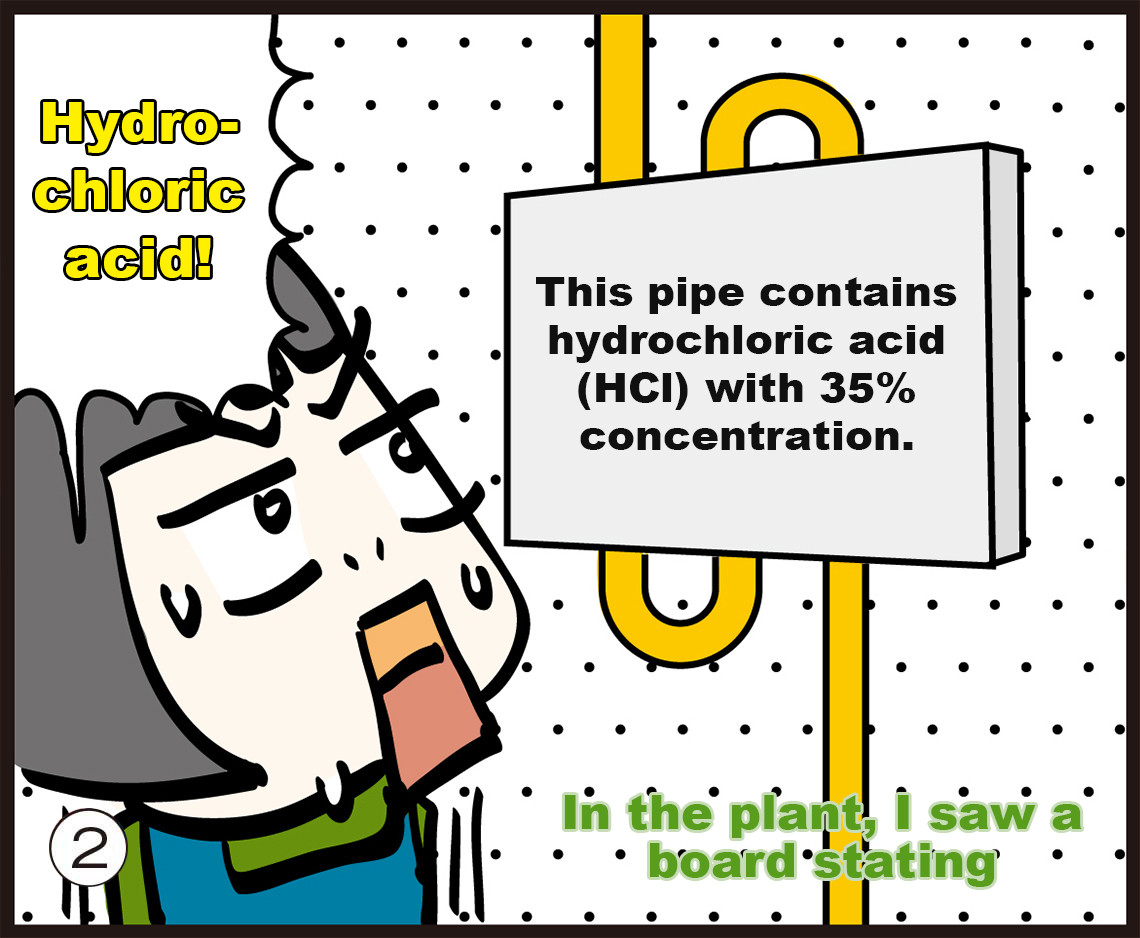

I had imagined that any industrial plant would be incredibly noisy. So the quietness of Niihama Nickel Refinery we visited this time came as a great surprise to me and, indeed, to all of us.

Only in the building where electrodeposition is performed did we encounter an exception to this general quietness. While stripping plates were being hoisted and transported from the electrolytic cells to the nickel recovery site, a peculiarly cheerful electronic sound rang out—something totally different from what you would expect to hear in a factory—to alert people in the vicinity. Relishing the experience, Ms. Takagi exclaimed, “It’s like a giant claw crane in a gigantic amusement arcade!”

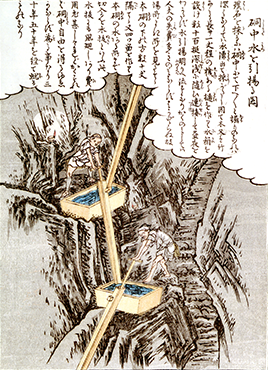

We also visited the Besshi Copper Mine Memorial Museum, a short drive from the plant. Some 10,000 satsuki azaleas adorn its rooftop garden: an inspired choice since satsuki also means May in Japanese, the very month in which the Besshi Copper Mines received a license to operate and these glorious plants come into bloom.

When we visited, the satsuki azaleas had just started to bloom and a delicate fragrance filled the air. It is a popular spot for photographers and there were quite a few people with cameras capturing the magnificent floral show. I took a few snaps with my smartphone.

EN

EN