The chemical industry is also tackling the challenge of achieving carbon neutrality. Sumitomo Bakelite Co., Ltd., a leading manufacturer of semiconductor encapsulation materials, with core businesses in automotive resins and pharmaceutical packaging films, is working toward a breakthrough that is attracting attention globally: creating plastics from plant-based materials.

Sumitomo Bakelite Co., Ltd. began researching the production of plastics from plant-based raw materials in 2010. That February, the company, in collaboration with the Research Institute of Innovative Technology for the Earth (RITE), established the Green Phenol and High Performance Phenolic Resin Production Technology Research Association (GP Association). This initiative aimed to develop fundamental technologies for producing phenolic resins and other materials through bioprocesses that use sugar derived from inedible (non-food) plant resources as a raw material.

The GP Association was later reorganized as Green Phenol Development Co., Ltd. (GPD). After GPD established production technology, the company changed its name to Green Chemicals Co., Ltd., (GCC) in April 2018, aiming to commercialize its innovations.

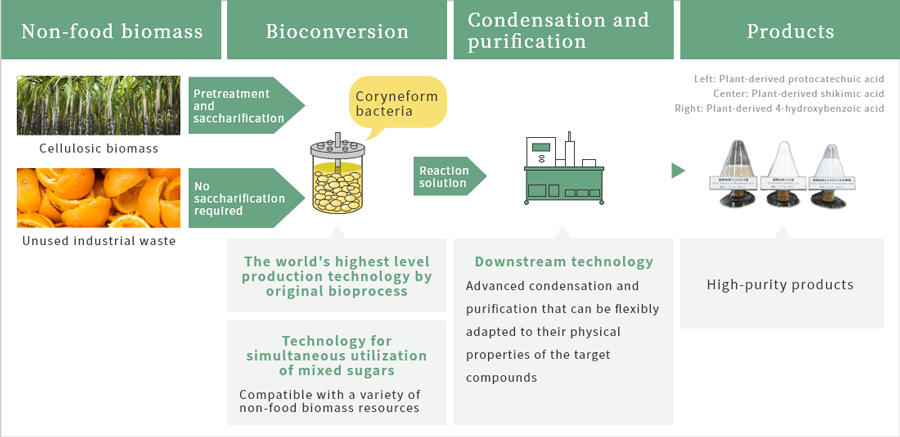

The essence of bioprocess technology is the use of microorganisms. Green Chemicals utilize coryneform bacteria, a microorganism developed by RITE through genetic recombination technology, to efficiently produce target compounds from plant-based sugars.

In the bioprocess, sugars are first extracted from plant-based raw materials and then fed to microorganisms. The microorganisms metabolize the sugars and produce the desired compounds, such as phenol, which is used in phenolic resins. This process is similar to how humans ingest glucose and convert it into various substances in the body.

In the bioprocess using coryneform bacteria, sugars are not used for cell growth but are instead used to produce useful substances. Unlike chemical production processes, this technology does not require significant energy consumption to create high-temperature, high-pressure conditions. Only useful substances are produced under ambient temperature and normal pressure conditions. With minimal energy requirements and little impact on the environment, this breakthrough biotechnology is a dream come true.

Through Green Chemicals, Sumitomo Bakelite Co., Ltd. is currently focusing on the production of four compounds: 1) phenol, 2) 4-hydroxybenzoic acid (4-HBA), 3) shikimic acid, and 4) protocatechuic acid.

Firstly, phenol. By polymerizing formaldehyde, phenol becomes thermosetting phenolic resins with higher heat resistance than other resins. Phenolic resins are easy-to-handle plastic materials known for their resistance to heat and impact. However, they have a drawback in that they cannot be reformed once shaped, even by applying heat. In other words, they cannot be crushed and melted, which makes recycling difficult. But the use of plant-based phenol would make it possible to reduce the carbon footprint of the final product.

Moreover, phenolic resins are the foundational business of Sumitomo Bakelite Co., Ltd. The company’s long-term goal is to produce phenolic resins from plant-based raw materials and gradually replace those produced through chemical processes.

Secondly, 4-hydroxybenzoic acid. This compound is essential for the manufacture of liquid crystal polymers, which are sophisticated resins used in components that require excellent dimensional stability, such as connectors in PCs and smartphones. Of the plant-based compounds handled by Green Chemicals, the efforts toward practical application are most advanced for 4-hydroxybenzoic acid.

Thirdly, shikimic acid. Shikimic acid is a key raw material for anti-influenza drugs and other products. Traditionally, it has been extracted from star anise and certain other plants, but there are issues such as fluctuating yields due to climate change and the energy consumption required in the extraction process. A production method using microorganisms could potentially resolve these issues.

Fourthly, protocatechuic acid. This acid is a natural polyphenolic antioxidant found in medicinal plants. It is known for its diverse pharmacological efficacy, including antibacterial, antiviral, anticancer, anti-inflammatory, anti-aging, and anti-atherosclerosis properties. It is also used as a raw material for cosmetics and as an additive in adhesives. Since the plant-based protocatechuic acid offers the same functionality as conventional chemical syntheses, its availability could present an attractive value proposition in the market.

How can the plant materials needed to produce these compounds be sourced? One approach being considered is the effective utilization of food waste, such as, pomace generated as a byproduct of the production of fruit juices. Citrus fruits, like mandarin oranges, are particularly suitable as raw materials because of their high sugar content. If initiatives to repurpose food residues progress, this could provide a solution to two issues: waste reduction and securing a stable supply of raw materials.

However, there are still many challenges to overcome before full-scale commercialization. The highest hurdle is that, while plant-based plastic products are widely regarded as wonderful, they are generally more expensive than conventional synthetic products. For automotive parts and other products that use phenolic resins, procuring materials in large quantities at low cost is essential, and so the momentum to switch to plant-based phenolic resins has been slow.

Furthermore, when mass producing resins, it is currently difficult to secure a stable supply of the necessary plant-based raw materials, even if food waste is utilized. This is because, even when alternative plant materials are used, their yields may fluctuate depending on climatic conditions, and there is also competition with products intended for other purposes.

Establishing mass production technology is also a challenge. The transition from laboratory-scale production to industrial-scale mass production, capable of meeting high demand, involves many technical issues that must be addressed.

Green Chemicals plans to approach these issues step by step. Initially, the company intends to establish a track record in markets with relatively high cost tolerance, such as the advanced materials field, and then gradually expand into mass-produced products.

An executive at Green Chemicals states the goal: “In the future, we aim to replace chemical products made from petroleum-derived raw materials with 100% plant-based raw materials.” While this goal will not be easy to achieve, the company is committed to steadily advancing technological development and market cultivation toward the realization of a carbon-neutral society. Sumitomo Bakelite Co., Ltd. and Green Chemicals are taking concrete steps toward helping the chemical industry establish sustainable manufacturing processes.

EN

EN

Journalist Shumon Mikawa on Sumitomo’s DNA

Journalist Shumon Mikawa on Sumitomo’s DNA