Construction machinery fulfills a vital behind-the-scenes role in supporting our daily lives. It’s essential for urban development, infrastructure projects such as dam construction, and disaster recovery efforts. Hydraulic excavators, asphalt pavers for road maintenance, and specialized machines for demolition, metal recycling, and forestry are just a few examples. Sumitomo Construction Machinery is a leading manufacturer of these essential machines.

In addition to high productivity, construction machinery must be energy-efficient to reduce environmental impacts and designed with a relentless focus on safety. Sumitomo Construction Machinery has been developing eco-friendly products to meet these demands.

For example, hydraulic excavators, the company’s flagship products, are often used in harsh environments, such as for digging and loading in complex terrain, where conditions can vary significantly from one location to another. As a result, improving fuel efficiency is no easy task. Furthermore, comparing fuel efficiency among manufacturers is more challenging than with vehicles designed for use on flat roads.

While Sumitomo Construction Machinery was considering how to highlight the energy-saving performance of its products, its hydraulic excavator won the 2007 Energy Conservation Grand Prize (organized by the Energy Conservation Center, Japan). This was the first time a company in the construction machinery industry had won this award based on a comparison of fuel efficiency performance conducted by experts using actual equipment. Since then, the company’s flagship models (the mainstay 20-ton class) have been recognized with the Energy-Efficient Machinery Award in 2013 and the Energy-Efficient Machinery and System Award in 2018 (both organized by the Japan Machinery Federation), achieving the remarkable feat of winning awards for three consecutive generations.

In addition to manufacturing energy-efficient construction machinery, the company is advancing decarbonization in its transportation methods. Construction machinery, often referred to as heavy equipment, is extremely heavy. As a result, the question of which transportation method should be used for deliveries and for sending equipment back for repairs involves important issues. Sumitomo Construction Machinery has long been committed to a modal shift (i.e., transitioning to transportation methods with lower environmental impacts), reducing reliance on truck transport by shifting to rail transport for parts and marine transport for products, in order to minimize carbon dioxide emissions during transportation.

The construction and civil engineering industry operates in a challenging environment. In recent years, urban development has expanded, while aging social infrastructure—such as roads, buildings, and water pipes—has led to a growing number of repair projects. At the same time, a serious labor shortage in the industry has made productivity improvement an urgent priority. To address this, Japan’s Ministry of Land, Infrastructure, Transport and Tourism launched the “i-Construction” initiative in fiscal 2016, promoting the use of information and communication technology (ICT) to enhance efficiency at construction and civil engineering sites. Sumitomo Construction Machinery is actively supporting this initiative by leveraging ICT to the fullest extent in its “ICT construction” approach.

A key technology in ICT construction is the 3D (three-dimensional) system. Drones are used for surveying construction and civil engineering sites, generating 3D data that is then overlaid with the 3D design data of the finished surface. The 3D design incorporates BIM/CIM (Building Information Modeling /Construction Information Modeling).

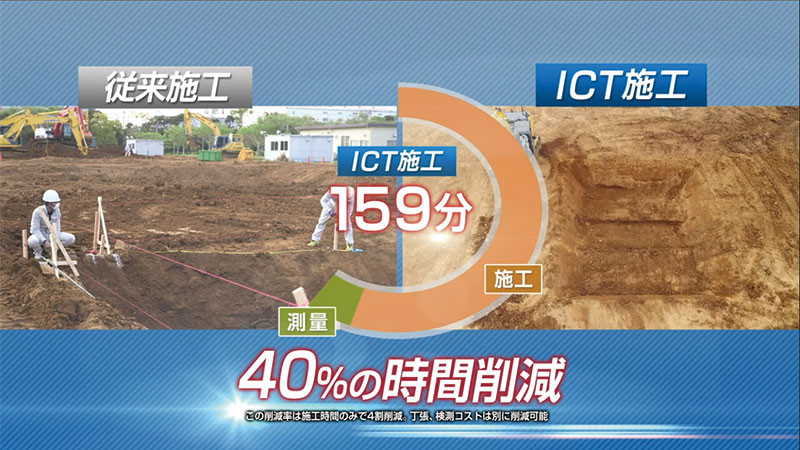

During construction, excavation instructions are displayed on a monitor in the operator’s cab based on soil positioning data from the GNSS (Global Navigation Satellite System) and the inclination of the construction machinery. This allows operators to work efficiently while monitoring precise construction positions in real time. The “visualization” function allows skilled workers to work faster and helps newcomers perform high-precision tasks with confidence. To support training, the company has established an ICT training center in Kariya City, Aichi Prefecture, where participants can experience 3D surveying and test-operate ICT-enabled construction machinery.

ICT construction has reduced the need for manual surveying, improving accuracy and cutting total surveying and construction time by 40%. As a result, diesel fuel consumption has been reduced, which in turn reduces the number of tanker truck trips needed to refuel construction machinery.

Although the 3D system helps reduce the number of measurement tasks and guides, additional measures are needed to eliminate industrial accidents entirely. For this purpose, Sumitomo Construction Machinery developed the field view monitor (FVM) to prevent contact between machinery and people. Multiple cameras are installed at the rear of the construction machinery, providing operators enable with a 270-degree aerial view of the blind spot behind the machine (for standard models) on a monitor. This allows operators to check for any individuals in the vicinity before moving the equipment.

Moreover, Sumitomo Construction Machinery has introduced the FVM2, which automatically analyzes video images and, upon detecting a person, alerts the operator with both a monitor display and an audible warning, Additionally, the FVM2+ is equipped with a function that accurately detects individuals wearing safety vests and automatically decelerates or stops the machinery when a person and the machine come into close proximity. The company remains committed to its “Safety First” principle, ensuring the highest level of protection for people.

Sumitomo Construction Machinery’s mission established in 2024 expresses its commitment to contributing to a low-carbon society through new technologies and environmentally responsible manufacturing, while also encouraging employees to actively move toward a more sustainable and prosperous future in every aspect of their work.

Inspired by this vision, Sumitomo Construction Machinery has already prototyped an electric construction machine and is also working on next-generation models that utilize hydrogen fuel and biofuels. Furthermore, the company has begun exploring the use of generative AI, such as ChatGPT, to assist in programming and optimizing construction machinery operations.

EN

EN

Journalist Junichiro Hori on Sumitomo’s DNA

Journalist Junichiro Hori on Sumitomo’s DNA