Social Issues addressed by Sumitomo —Compass for the Future—

Local production of wiring harnesses for local consumption

Automated manufacturing targeting both commercial success and resolution of social issues

Local production for local consumption

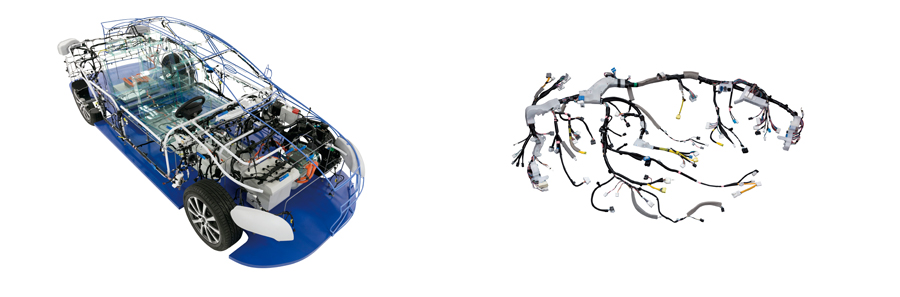

Local production for local consumptionSumitomo Wiring Systems’ core business is the manufacture and sale of wiring harnesses primarily for automobiles. The company’s other products include electronic components and electric wires and cables. A wiring harness is an assembly of electrical wires and cables that transmit electrical power, communication signals, and information. Demand for wiring harnesses for automobiles is increasing as they are indispensable for power supply and information communication in vehicles. Operating in over 30 countries and territories around the world, Sumitomo Wiring Systems has a leading share of the global market for wiring harnesses for automobiles.

Rather like the human body’s networks of blood vessels and nerves, wiring harnesses transmit power and signals throughout a vehicle. Wiring harnesses consisting of hundreds of wires are assembled by painstakingly placing connectors and electronic control units (ECUs) in accordance with drawings corresponding to vehicle models.

Automation of wiring harness manufacturing is difficult owing to its complexity, and even today, Sumitomo Wiring Systems employs many people to manufacture these products at its sites around the world. From the viewpoint of cost competitiveness, the company manufactured wiring harnesses for North America at plants in ASEAN countries, making long-distance transportation, along with the associated CO2 emissions, unavoidable. Moreover, the recent global shortage of semiconductors and the impact of the COVID-19 pandemic have highlighted the drawbacks of the labor-intensive business model. This is the context in which Sumitomo Wiring Systems is establishing a system geared to local production for local consumption.

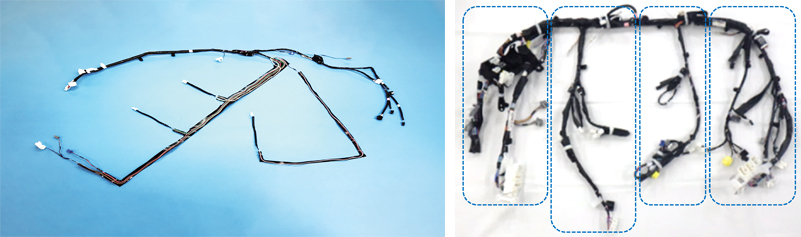

In order to realize local production for local consumption, Sumitomo Wiring Systems is pursuing initiatives to automate manufacturing processes previously considered unsuited to automation. Examples of such initiatives include application of the set operation, which is particularly advantageous in terms reducing man-hours, and the introduction of split wiring harnesses.

Even with the conventional labor-intensive operation, about 15% of the entire wiring harness manufacturing process is automated, but the practical application of the set operation whereby cutting and crimping of wires are executed automatically, has led to a significant reduction in lead time. By integrating e-STEALTH W/H® with an automatic assembly process for split harnesses, whereby each harness is divided into four or five modules, the company is aiming to achieve high-variety production with smaller part counts. The automation rate has been increased to about 50% on a model line. The higher the automation rate, the more feasible manufacture of wiring harnesses in regions with high manufacturing costs to promote local production for local consumption becomes, with the additional benefit of eliminating the CO2 emissions associated with long-distance transportation.

Sumitomo Wiring Systems has also developed aluminum wiring harnesses that enable a reduction of around 12% in vehicle weight compared with conventional products. Lightweight wiring harnesses from the manufacturer with the leading global market share are expected to make a substantial contribution to the reduction of CO2 emissions from vehicles on the move.

Although there tend to be trade-offs between tackling social issues and attaining strictly commercial objectives, Sumitomo Wiring Systems will seek to resolve such issues while, at the same time, achieving business growth.

Read about initiatives to achieve a low-carbon society, aiming at net-zero greenhouse gas emissions since these emissions are implicated in global warming.

In view of ongoing globalization and the growing complexity of supply chains, companies need to respond appropriately to issues in supply chains.

The pace of workstyle reform is accelerating as the COVID-19 pandemic has prompted numerous companies to embrace novel ways of working.

For companies, the COVID-19 pandemic has brought the crucial importance of employee health into sharp focus.

Accelerating global warming poses serious business risks. Accordingly, companies need to formulate strategies and implement specific countermeasures from a medium- to long-term perspective.

Spurred by efforts to reduce environmental impacts and in line with increasing social needs, replacement of gasoline-powered vehicles with electric vehicles is accelerating.

Vigorous initiatives are afoot to tackle social issues by revitalizing communities and the interpersonal relationships that bind them together.

Poverty persists in contemporary Japan and the existence of child poverty is a grave concern.

In view of the continuing decline of Japan’s working age population, due to population aging coupled with a low birthrate, development of the next generation is an urgent issue.

The rapid progress in medicine in recent years is largely due to the efforts of not only universities and other research institutions but also of companies to develop cutting-edge technologies.

Numerous initiatives to promote industry and commerce at the regional and community level are underway, involving the use of renewable energy and thus contributing to decarbonization.

One-third of food produced is lost or wasted globally, amounting to about 1.3 billion tons per year. Food loss and waste is a pressing issue in need of a solution.

Companies are addressing a wide range of issues so that people and companies can coexist in harmony with the global environment.

In addition to natural disasters, there are various types of hazards whose nature, incidence and severity are changing with the times. Resilience and flexibility are indispensable in dealing with them.

Read about initiatives to achieve sustainable regional revitalization. The attributes and resources that each region can offer are leveraged to strengthen local economies and overcome the problem of population decline.